Textile Industry

Boilers are essential in the textile industry, providing steam and hot water for processes like dyeing, printing, drying, and finishing fabrics. They help set colors, remove moisture, and improve fabric texture. Boilers also power washing machines and humidifiers, ensuring proper cleaning and optimal conditions. In some cases, they generate electricity through cogeneration, enhancing energy efficiency. Overall, boilers are key to fabric treatment, drying, pressing, and power generation in textile manufacturing.

Bright Engineering

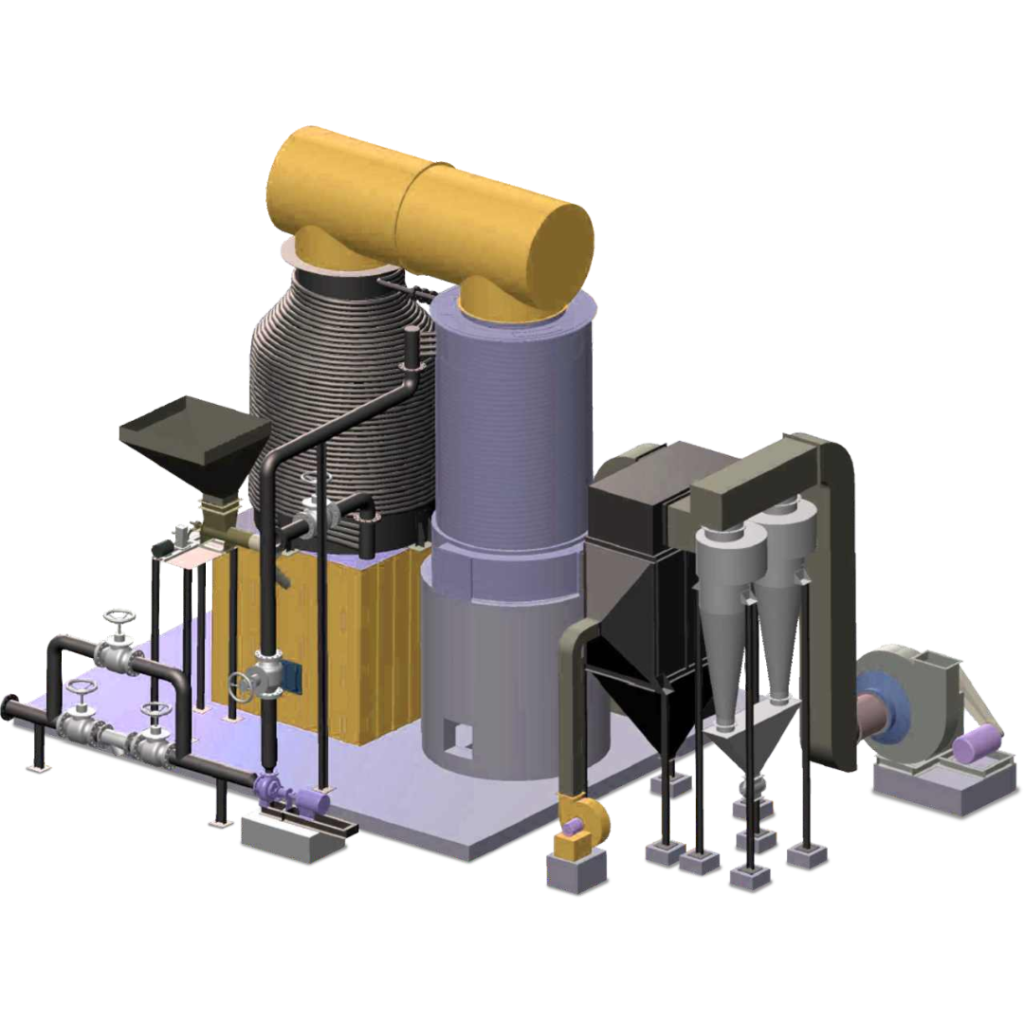

Founded in 2003 in Coimbatore, India, Bright Engineering is a trusted manufacturer and supplier of premium boilers and heaters built to ASME, ISO, DIN, and IBR standards. We specialize in designing steam boilers with capacities ranging from 100 to 20,000 kg/hr, capable of handling pressures up to 32 kg/sq.cm², and compatible with various fuels. Additionally, we offer essential components such as dust collection systems, economizers, and air pre-heaters.

Our products are recognized for their reliability, efficiency, easy installation, and low maintenance. The range includes pneumatic steam boilers, solid-fuel-fired steam generators, industrial boilers, and dry back boilers. To ensure exceptional quality and performance, we also provide boiler fabrication services, utilizing advanced engineering tools and modern technology.